Bartoš-Delta Ltd., Oravská 2, 821 09 Bratislava, Slovakia, www.bartos-delta.sk

Company Registration No.: 46057340, VAT: SK2023212114, Trade register of Court of Justice Bratislava I, part Sro, number 71283/B

Capital: 5,000 €, Paid up: 5,000 €

Last update: February 8-th 2023

Bartoš-Delta Ltd. provides the maintenance service for plasma or waterjet cutting tables owners. In the last year we serviced the customers in the United Kingdom, Austria, Hungary, Latvia, Lithuania, Poland, and Slovakia. We provide standard maintenance, one-year maintenance coverage, inspection, replacement parts, and consumables based on the customers needs. Inspection allows our customers to get an up to date picture of the condition of their production tool and organize the production accordingly. The result of the inspection is a list of defects and tasks that needs to be carried out before the machine is ready to work without unforeseen breakdowns. Maintenance and the removal of these deficiencies is carried out in the less busy time periods, and on a date planned and agreed on in advance. With regular maintenance the lifespan of your machine can be greatly extended, and the precision and reliability improved.

Bartoš-Delta Ltd. provides the maintenance service for plasma or waterjet cutting tables owners. In the last year we serviced the customers in the United Kingdom, Austria, Hungary, Latvia, Lithuania, Poland, and Slovakia. We provide standard maintenance, one-year maintenance coverage, inspection, replacement parts, and consumables based on the customers needs. Inspection allows our customers to get an up to date picture of the condition of their production tool and organize the production accordingly. The result of the inspection is a list of defects and tasks that needs to be carried out before the machine is ready to work without unforeseen breakdowns. Maintenance and the removal of these deficiencies is carried out in the less busy time periods, and on a date planned and agreed on in advance. With regular maintenance the lifespan of your machine can be greatly extended, and the precision and reliability improved.

In the year 2014 our new control system (CS) has been finished. The compact design ensures small space requirements. The system is based on one standard PC. Three transformers, power source (24V/10A), and the terminals are located in the lower part of the CS cabinet. There are four cooling fans and up to eight servo systems in the middle section of the control system. The cooling fans turn on automatically if the temperature in the CS rises above 40°C (104°F). The upper section of the cabinet holds the PC and the display. Communication with the servo systems, gantry modules and suction zones is established via serial links connected to the PCCM3 module. The operator has a keyboard, mouse, 19" monitor, and an external USB port at his disposal. The PC boots into two separate operating systems. The cutting software (Aton) itself runs under DOS6.22, but the operator has all comfort of Windows 7 to prepare the cutting plan, and use all network based features.

In the year 2014 our new control system (CS) has been finished. The compact design ensures small space requirements. The system is based on one standard PC. Three transformers, power source (24V/10A), and the terminals are located in the lower part of the CS cabinet. There are four cooling fans and up to eight servo systems in the middle section of the control system. The cooling fans turn on automatically if the temperature in the CS rises above 40°C (104°F). The upper section of the cabinet holds the PC and the display. Communication with the servo systems, gantry modules and suction zones is established via serial links connected to the PCCM3 module. The operator has a keyboard, mouse, 19" monitor, and an external USB port at his disposal. The PC boots into two separate operating systems. The cutting software (Aton) itself runs under DOS6.22, but the operator has all comfort of Windows 7 to prepare the cutting plan, and use all network based features.

Front view (without covers) Rear view (without covers) Monitor and power source

The servo systems are based on a 32-bit DSP processor. Every servo system is comprised of a cooler, power module with an adaptive current regulator, analog/binary I/O module and a main control board with a processor. The immediate data can be seen on a 4-digit display on the front of the servo, where you can observe data such as servo status, actual current when the servo is in use, and error status in case of a malfunction. They are interconnected through a serial communication link, which is connected to the PCCM3 module located in the motherboard’s PCI slot, with automatic impedance termination in the last servo on the link. Servo systems are interchangeable; they differ only in the address set in the processor module. The servo systems get all the parameters after the cutting software Aton starts up.

The servo systems are based on a 32-bit DSP processor. Every servo system is comprised of a cooler, power module with an adaptive current regulator, analog/binary I/O module and a main control board with a processor. The immediate data can be seen on a 4-digit display on the front of the servo, where you can observe data such as servo status, actual current when the servo is in use, and error status in case of a malfunction. They are interconnected through a serial communication link, which is connected to the PCCM3 module located in the motherboard’s PCI slot, with automatic impedance termination in the last servo on the link. Servo systems are interchangeable; they differ only in the address set in the processor module. The servo systems get all the parameters after the cutting software Aton starts up.

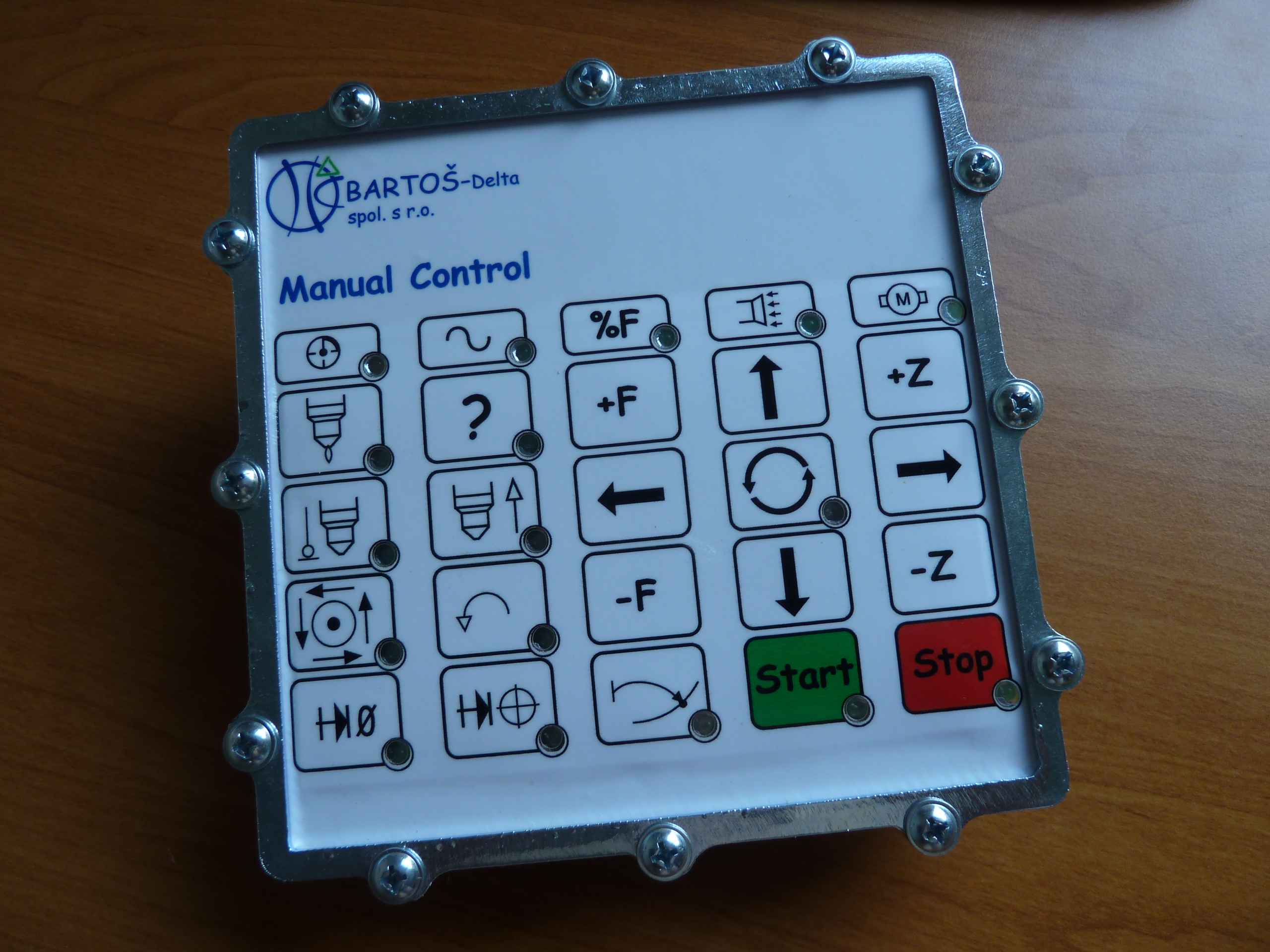

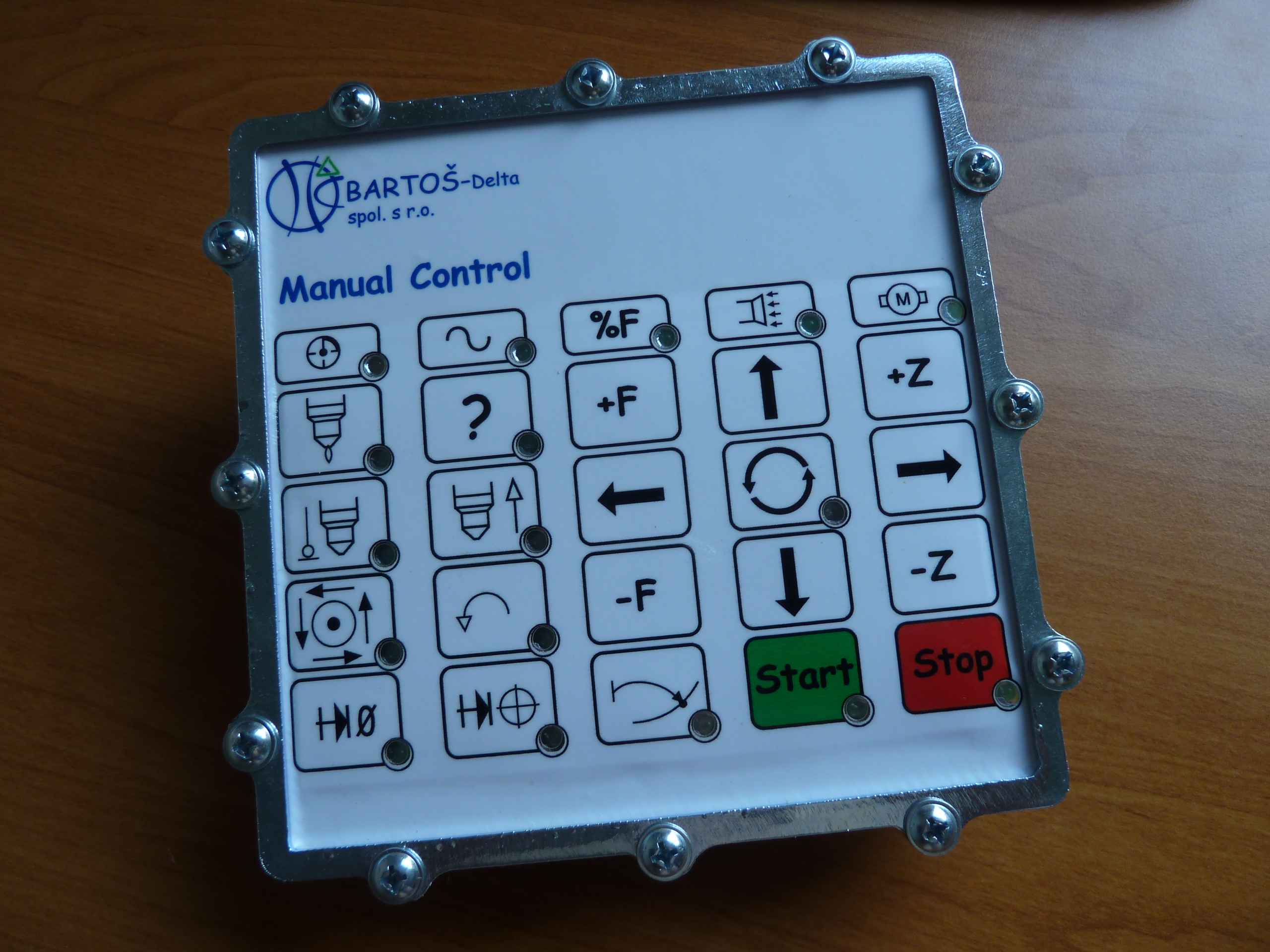

Servo systems (in stand-by) MC Module (Manual Control)

The Control System View with covers MCD Module (Manual Control with Display)

The control system is a good replacement for old or out of order systems. Because various cutting tables exists from different vendors, consultation is needed before installation.

The control system is a good replacement for old or out of order systems. Because various cutting tables exists from different vendors, consultation is needed before installation.

We focus mainly on Hypertherm, Kjellberg and Daihen plasma sources. We can deliver replacement parts and consumables from the original manufacturer or from Thermacut as well.

We focus mainly on Hypertherm, Kjellberg and Daihen plasma sources. We can deliver replacement parts and consumables from the original manufacturer or from Thermacut as well.

We can offer the fuzzy digital flow meter with thermometer into the plasma sources. In some plasma sources it is possible that the cooling liquid is not flowing, yet the plasma source can be started. Under this condition the torch is not cooled, consequently the torch can be damaged. The flow meter tolerates some fluctuations in flow, but under preprogrammed limit the plasma source is turned off to avoid the plasma torch damage. The cooling water flow is displayed for 7 seconds, in the next second the water temperature is on the display. The temperature has no influence to the running plasma source and it is the information for personal only.

We can offer the fuzzy digital flow meter with thermometer into the plasma sources. In some plasma sources it is possible that the cooling liquid is not flowing, yet the plasma source can be started. Under this condition the torch is not cooled, consequently the torch can be damaged. The flow meter tolerates some fluctuations in flow, but under preprogrammed limit the plasma source is turned off to avoid the plasma torch damage. The cooling water flow is displayed for 7 seconds, in the next second the water temperature is on the display. The temperature has no influence to the running plasma source and it is the information for personal only.

Contact us, please

Contact us, please

Bartoš-Delta Ltd., Oravská 2, 821 09 Bratislava, Slovakia

Business: Tomášikova 30, 821 01 Bratislava, Slovakia

Dipl. Eng. Karol BARTOŠ mobil: +421 911 221 562, e-mail: bartos@bartos-delta.sk

Bartoš-Delta Ltd. provides the maintenance service for plasma or waterjet cutting tables owners. In the last year we serviced the customers in the United Kingdom, Austria, Hungary, Latvia, Lithuania, Poland, and Slovakia. We provide standard maintenance, one-year maintenance coverage, inspection, replacement parts, and consumables based on the customers needs. Inspection allows our customers to get an up to date picture of the condition of their production tool and organize the production accordingly. The result of the inspection is a list of defects and tasks that needs to be carried out before the machine is ready to work without unforeseen breakdowns. Maintenance and the removal of these deficiencies is carried out in the less busy time periods, and on a date planned and agreed on in advance. With regular maintenance the lifespan of your machine can be greatly extended, and the precision and reliability improved.

Bartoš-Delta Ltd. provides the maintenance service for plasma or waterjet cutting tables owners. In the last year we serviced the customers in the United Kingdom, Austria, Hungary, Latvia, Lithuania, Poland, and Slovakia. We provide standard maintenance, one-year maintenance coverage, inspection, replacement parts, and consumables based on the customers needs. Inspection allows our customers to get an up to date picture of the condition of their production tool and organize the production accordingly. The result of the inspection is a list of defects and tasks that needs to be carried out before the machine is ready to work without unforeseen breakdowns. Maintenance and the removal of these deficiencies is carried out in the less busy time periods, and on a date planned and agreed on in advance. With regular maintenance the lifespan of your machine can be greatly extended, and the precision and reliability improved.